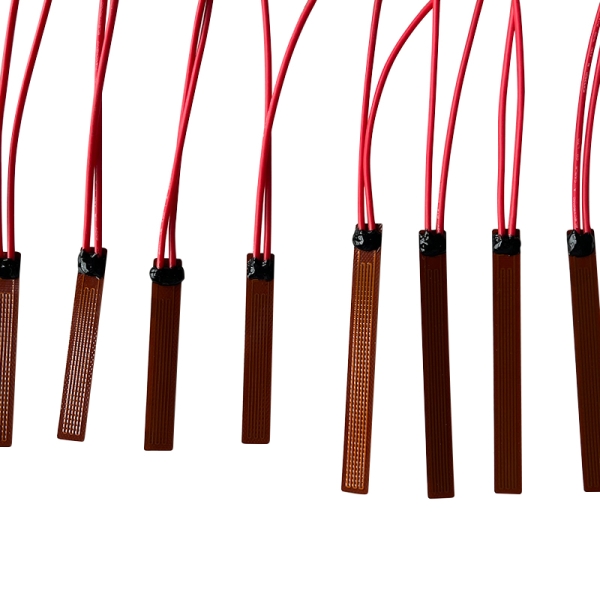

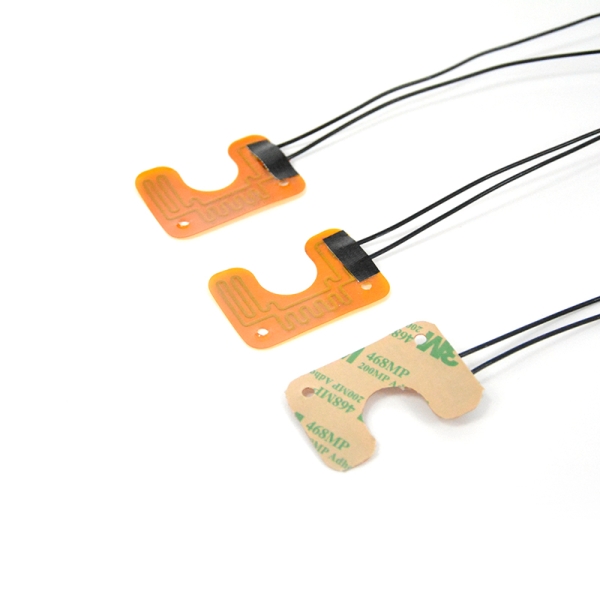

Polyimide Heater

Aerospace Heaters

Polyimide film heaters play an important role in the aerospace field, especially in extreme environments such as high altitude and space, meeting the heating needs of spacecraft and aviation equipment

Product Introduction

Polyimide film heaters play an important role in the aerospace field, especially in extreme environments such as high altitude and space, meeting the heating needs of spacecraft and aviation equipment. Its light weight, high efficiency, durability and flexibility make it an ideal choice for temperature control in aerospace and aviation. The following are specific applications of polyimide film heaters in the aerospace field:

1. Temperature control and prevention of low-temperature failure of electronic equipment

Electronic component heating: Spacecraft will experience extreme temperature differences in space, from high temperatures in direct sunlight to extreme cold in the shadow. Polyimide film heaters can stabilize the operating temperature of electronic equipment and prevent electronic component failure caused by low temperature.

Communication equipment and sensor heating: The communication and sensor equipment of spacecraft are susceptible to low temperatures. Film heaters can keep them within the operating temperature range to ensure the normal operation of the equipment and the stability of signal transmission.

2. Antifreeze and insulation of fuel and liquid

Propellant heating: Rockets and satellites are in extreme low temperatures, and fuel is easy to solidify, affecting the normal operation of the propulsion system. Polyimide film heaters can provide precise heating to ensure that the fuel remains fluid at low temperatures.

Heating of liquid storage systems: For storage systems in extremely low temperature environments such as liquid oxygen and liquid nitrogen, in order to prevent the freezing of liquids, polyimide film heaters can be installed on the surface of pipes and storage containers to prevent the freezing of fluids and improve system efficiency.

3. Low temperature and seismic protection of structures and surfaces

Structural heating: In the space environment, the structure of the material will produce stress due to low temperature shrinkage, affecting the stability of the spacecraft. Polyimide heaters can be applied to external structures to provide moderate heat to prevent structural deformation caused by low temperatures.

Anti-vibration and impact resistance: The softness and fit of the film heater allow it to be installed on complex surfaces, providing flexible heating under extreme conditions and reducing equipment fatigue caused by vibration.

4. Lightweight design and efficient use of energy

Lightweight and flexible characteristics: The polyimide film is very light and will not add extra burden to the aircraft. At the same time, the film heater has a small thickness and can be fitted to various complex surfaces and structures, with strong adaptability.

Low power consumption and high efficiency: The film heater can still maintain a good heating effect at low power, meet the needs of energy restrictions in spacecraft, achieve efficient use of energy, and extend the working time of the equipment.

5. Adaptability to vacuum environment and radiation resistance

Adaptability to vacuum conditions: Space is a vacuum environment. Polyimide film materials are resistant to high and low temperatures, have stable thermal properties, can work for a long time in a vacuum environment, and will not affect the equipment due to degassing or expansion problems.

Radiation resistance: Spacecraft are exposed to various cosmic radiation in space. Polyimide film has good radiation resistance and can be used for a long time in a strong radiation environment without aging.

6. Application scenarios

Satellites and space stations: used for temperature control, instrument heating, and structural heating to ensure the normal operation of equipment and personnel in extreme temperatures.

Mars and lunar rovers: In low-temperature extraterrestrial environments, polyimide heaters provide insulation for the interior of the vehicle body to ensure the normal operation of electronic equipment.

Unmanned probes: Polyimide film heaters can provide temperature protection for key components and protect equipment in environments outside the Earth's atmosphere.

Summary

Polyimide film heaters are widely used in the aerospace field due to their lightness, flexibility, radiation resistance, and adaptability to vacuum environments. Its stable heating performance in the space environment provides reliable temperature control support for spacecraft, detection equipment, and aircraft, and is an indispensable heating element in modern aerospace technology.