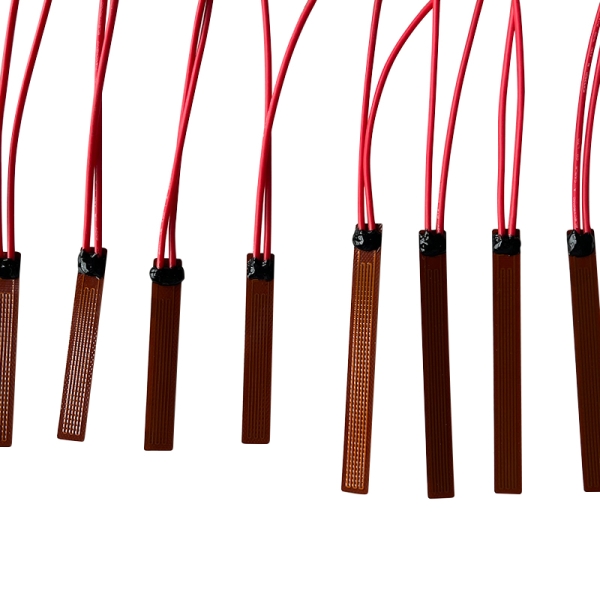

Polyimide Heater

3D printer heater

Application and advantages of polyimide film heaters in 3D printingPolyimide film heaters are widely used in 3D printing equipment, especially in the heating of printing workbenches and nozzles, to he

Product Introduction

Application and advantages of polyimide film heaters in 3D printing

Polyimide film heaters are widely used in 3D printing equipment, especially in the heating of printing workbenches and nozzles, to help achieve uniform and precise temperature control. This has an important impact on printing quality and efficiency, and can effectively reduce material warping and deformation, and improve printing effects.

Application

Print bed heating Polyimide film heaters are often used as printing bed heating elements for 3D printers, providing stable and uniform heating for the printing bed, so that the printing material can better adhere to the printing bed in the early stage of printing, thereby reducing the warping and deformation of the printed parts and ensuring the accuracy of the finished product.

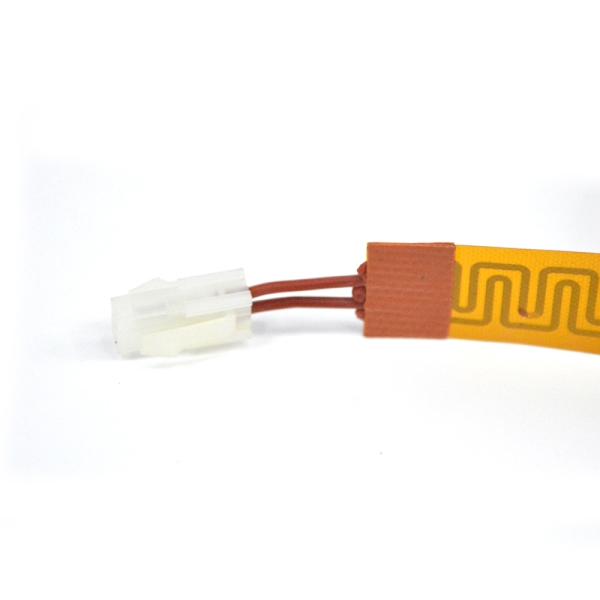

Nozzle temperature control heating The control of nozzle temperature is very critical for 3D printing, especially when different materials need to be printed, and the temperature requirements of different materials vary greatly. Polyimide film heaters are suitable for nozzle heating due to their precise temperature control performance, helping to keep the nozzle temperature constant during the printing process and achieve high-quality printing of different materials.

Ambient temperature control of closed printing chamber For some professional or industrial 3D printing equipment, polyimide film heaters can also be used to control the temperature of the closed printing chamber to avoid the impact of temperature fluctuations on the printing effect. By maintaining the temperature of the printing chamber, the material shrinkage caused by too fast cooling can be prevented, and the consistency of printing can be improved.

Advantages of polyimide film heaters

Uniform heating and precise temperature control The heating elements in the polyimide film heater are evenly distributed, which can provide highly uniform heat distribution and prevent temperature differences. With the intelligent temperature control system, its temperature control can be accurate to ±1℃, which helps the material to better adhere to the heating bed and nozzle and improve the printing stability.

Thin and flexible, easy to install The thickness of polyimide film heaters is usually 0.1-0.3 mm, light weight and good flexibility, which is easy to install on equipment components such as printing beds or nozzles. It is especially suitable for small spaces and complex designs of 3D printing equipment, reducing the overall weight of the equipment.

High temperature resistance and high insulation Polyimide materials have excellent temperature resistance and can usually work normally in the temperature range of -200℃ to 260℃, and have good electrical insulation. It can remain stable even at high temperatures, prevent short circuits or heat loss, and effectively extend the service life of the equipment.

Rapid heating and high thermal efficiency Polyimide film heaters have a fast heating speed, can reach the set temperature in a very short time, and maintain a constant temperature, which helps save preheating time and improve printing efficiency. At the same time, its energy conversion efficiency is high, reducing unnecessary power consumption and reducing operating costs.

Long life and low maintenance requirements Polyimide heater materials have excellent durability and corrosion resistance, and are suitable for long-term stable operation in frequent switching and high temperature environments. This long-life design reduces the frequency of heater replacement, reduces equipment maintenance requirements and downtime, and provides reliable temperature control support for 3D printing equipment.

Strong compatibility and adaptability to a variety of 3D printing materials There are many types of 3D printing materials, and different materials have different requirements for heated beds and nozzle temperatures. Polyimide film heaters can adapt to various temperature regulation needs, meet the temperature control requirements from PLA, ABS to engineering plastics (such as nylon, PC, etc.), and improve the versatility and adaptability of the equipment.

Summary

Polyimide film heaters have become ideal heating elements in 3D printing equipment due to their efficient temperature control, durability and flexibility, which can improve printing accuracy, reduce material deformation, and extend the service life of the equipment. In the heating of the print bed, nozzle temperature control and print chamber temperature regulation, polyimide film heaters not only improve printing efficiency, but also ensure the quality and consistency of the final product. These characteristics have made it widely used in consumer and industrial 3D printing equipment, and gradually become a standard component of high-performance 3D printers.