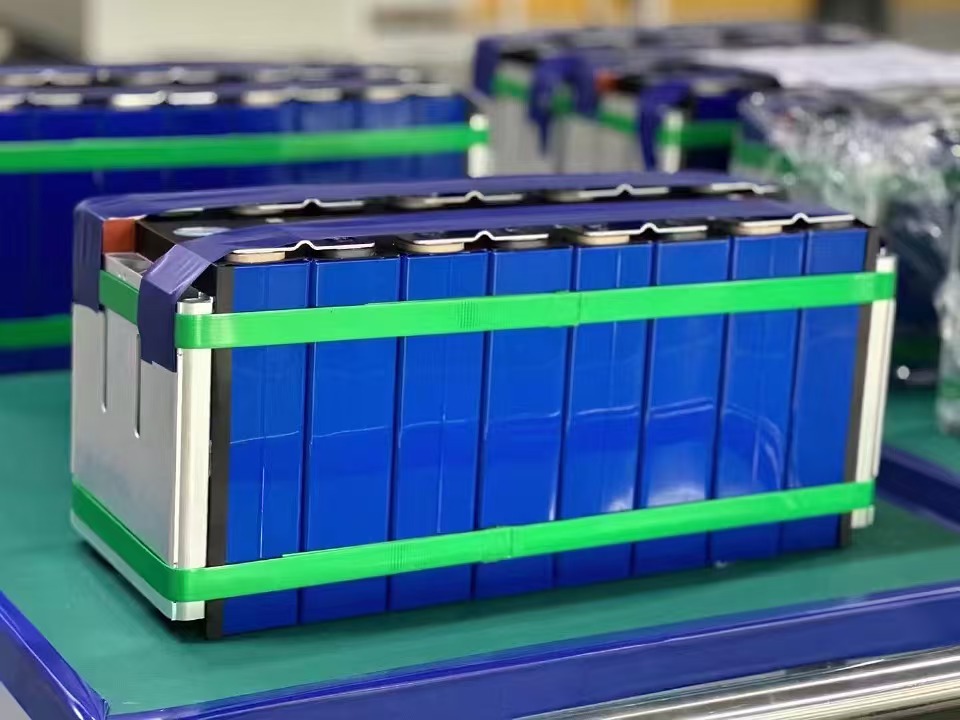

With the increasing impact of low temperature on the performance of electric vehicle batteries, especially in equipment such as forklifts that require efficient and continuous work, ensuring the efficient operation of power batteries in cold environments has become the key. We have specially developed a polyimide (PI) heating film designed for forklift power batteries to provide a comprehensive solution.

1. Excellent heating performance

Fast heating: PI heating film has excellent thermal conductivity and low heat capacity design, which can quickly heat the battery to the optimal operating temperature in a short time and reduce low temperature start-up delays.

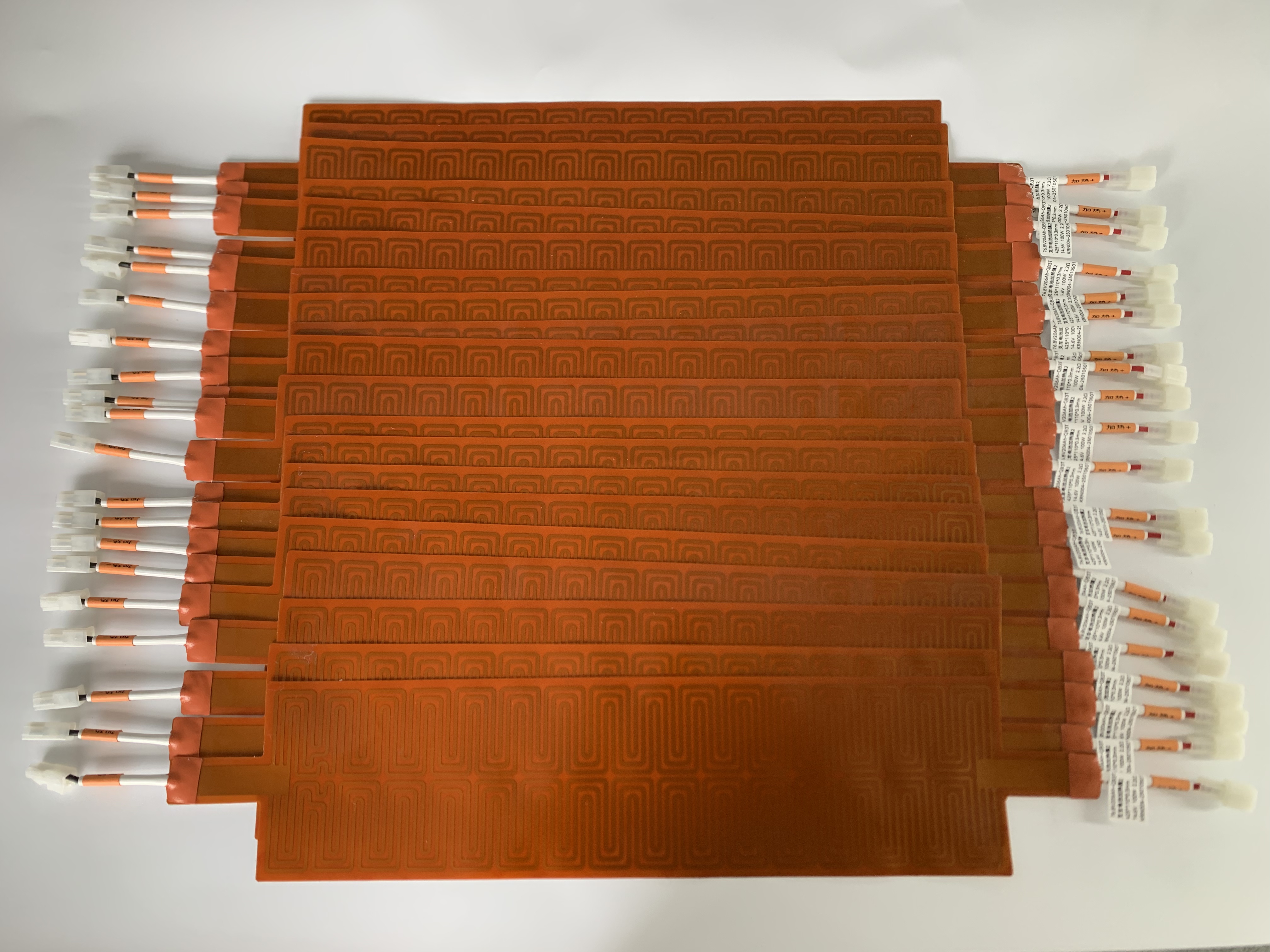

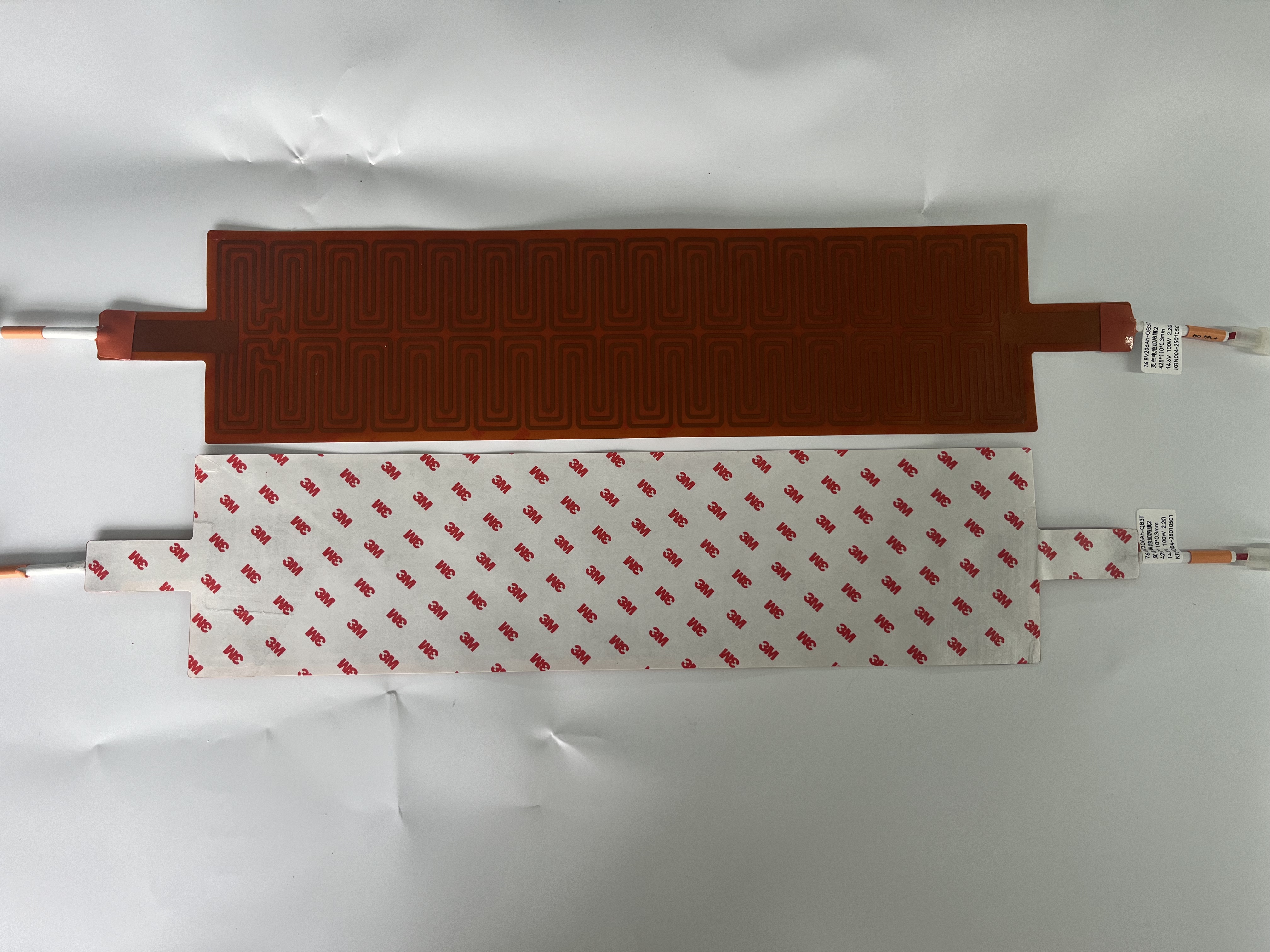

Uniform heating: The surface temperature of the heating film is evenly distributed to avoid local overheating or cold spots, and improve battery working efficiency.

2. Durability and stability

High and low temperature resistance: Polyimide material has a wide temperature operating range (-200℃ to 260℃), adapts to various extreme environmental conditions, and is not easy to age or deform after long-term use.

Chemical corrosion resistance: PI film has a strong tolerance to electrolytes, moisture and other corrosive chemicals, extending the life of the equipment.

Mechanical stress resistance: Good flexibility, can adapt to the complex installation requirements and vibration environment in the battery module.

3. Energy-saving and high-efficiency

Low-power operation: The optimized power density design ensures that while meeting the heating requirements, energy consumption is minimized and the long-term use cost is reduced.

Efficient heat conversion: The efficiency of converting electrical energy into thermal energy is as high as 95% or more, providing stable heating support for forklifts.

4. Safety and reliability

Self-limiting temperature function (optional): Avoid safety hazards caused by excessive temperature, automatically keep it within a safe range, and ensure the safety of batteries and heating films.

Overload protection: Equipped with overheating and short-circuit protection functions, it increases the overall safety and reliability of the system.

5. Flexibility and customization

Strong adaptability: PI heating film can be flexibly customized according to the size and structure of forklift batteries of different models to ensure perfect fit and optimal heat transfer effect.

Light and thin design: The thickness of the heating film is only tens of microns, which does not take up extra space and does not increase the burden on forklift batteries.

6. Wide range of application scenarios

All-weather operation: Whether it is outdoor forklift operation in extremely cold environments or used in special scenarios such as cold storage, it can ensure stable battery performance.

Compatible with multiple devices: In addition to forklift batteries, PI heating film can also be widely used in the heating needs of power batteries for logistics vehicles, engineering vehicles and other special vehicles.

7. Environmental protection and sustainable development

Environmentally friendly materials: PI materials are environmentally friendly polymer materials that meet various environmental regulations.

Reduce energy waste: Reduce battery performance loss and energy waste through efficient heating, and help the development of low-carbon transportation.

Welcome to contact us for more technical details and application solutions!