Silicone Rubber Heater

Silicone battery heating film

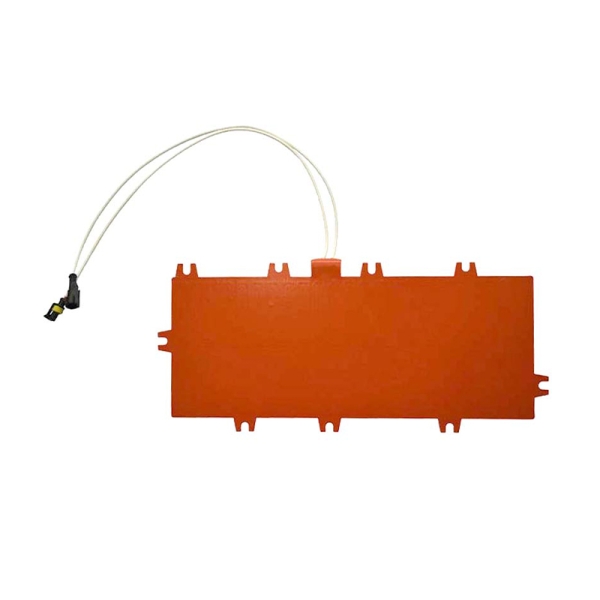

Silicone rubber lithium battery heating film is a heating element designed for lithium batteries. It is mainly used to heat and temperature control lithium battery packs in cold environments to ensure

Product Introduction

Introduction to Silicone Rubber Lithium Battery Heating Film

Silicone rubber lithium battery heating film is a heating element designed for lithium batteries. It is mainly used to heat and temperature control lithium battery packs in cold environments to ensure their normal working performance. Lithium batteries are prone to capacity attenuation and reduced charging efficiency in low temperature environments. Silicone rubber heating film helps lithium batteries maintain optimal operating temperature and improve their efficiency and service life by providing stable and uniform heat. This product is widely used in electric vehicles, energy storage systems, drones, power tools and other equipment that require lithium batteries.

Product Features:

Flexible Design Silicone rubber heating film adopts a flexible design and can be customized according to the shape of the battery pack to fit the surface of batteries of different sizes and shapes. Its thin film structure does not increase the volume and weight of the battery system, which is very suitable for installation in compact spaces.

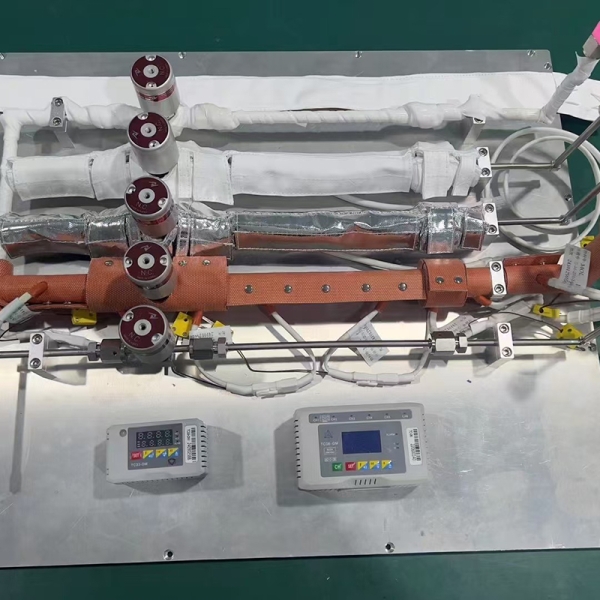

Efficient Heating The heating film has built-in evenly distributed heating wires (usually nickel-chromium alloys) that can quickly heat up and provide stable heat across the entire surface. It ensures that lithium batteries quickly reach the ideal operating temperature in low temperature environments and avoid battery performance degradation due to low temperatures.

High and low temperature resistance Silicone rubber materials can withstand extreme temperature changes, and the operating temperature range is usually -60°C to 250°C, so the heating film can be used for a long time in extremely cold or hot environments to ensure the stability and safety of the battery pack.

Excellent electrical insulation Silicone rubber has excellent electrical insulation properties. The heating film can effectively prevent safety hazards such as short circuit and leakage of the battery pack, and ensure safe operation in high voltage or complex electrical environments.

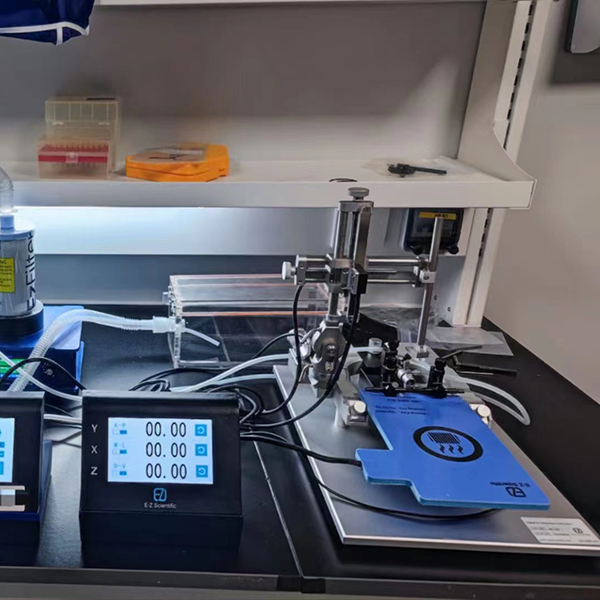

Accurate temperature control Silicone rubber lithium battery heating film can be used in conjunction with a temperature control system to automatically adjust the heating temperature to prevent overheating and unnecessary energy consumption. The thermostat can adjust the power output of the heating film in time according to the temperature changes of the battery to maintain a stable temperature.

Application scenarios:

Electric vehicles In electric vehicles, the performance of lithium batteries will drop significantly at low temperatures, resulting in a reduction in cruising range. Silicone rubber heating films can provide heating for the battery pack of electric vehicles, keep the battery pack in the best working condition in cold environments, and ensure the vehicle's endurance and charging efficiency.

Energy storage system The batteries of energy storage devices (such as solar or wind energy storage systems) may not operate normally in low temperature environments. Silicone rubber heating film can provide constant temperature protection for energy storage batteries to prevent the weakening of electrochemical reactions under cold conditions, thereby ensuring the stability of the energy storage system.

Drones and power tools Drones and power tools are usually used outdoors and are greatly affected by low temperature environments. The heating film can be installed inside or outside the battery pack to provide rapid heating for the lithium battery when it is started, ensuring the endurance and power output of the equipment at low temperatures.

Outdoor power supplies and portable devices Portable power supply devices used outdoors, such as mobile power supplies, outdoor battery packs, etc., are prone to rapid power consumption in cold outdoor environments. Silicone rubber heating film can effectively improve the working efficiency and service life of the battery, ensuring reliable power supply in harsh environments.

Product advantages:

High flexibility and customizability Silicone rubber heating film is extremely flexible and can be customized according to the shape of the battery pack to ensure the heating effect without increasing the size of the device. Its design is suitable for various battery modules, whether it is a large-size battery or a battery for a small device.

Fast and uniform heating The built-in high-efficiency heating element can quickly provide uniform heat to the battery, avoid local overheating and battery performance degradation, and ensure uniform heating and rapid start-up of the entire battery pack at low temperatures.

Safe and reliable Silicone rubber materials have high electrical insulation, high temperature resistance and corrosion resistance, ensuring the high safety of the heating film during use. Prevent risks such as leakage and short circuit, especially suitable for high-power battery packs in electric vehicles and energy storage equipment.

Extend battery life The heating film can maintain the optimal operating temperature of the battery in a low temperature environment, reduce the charging and discharging instability of lithium batteries caused by low temperature, and effectively extend the service life of the battery.

Energy saving and efficiency The silicone rubber lithium battery heating film can be used with a temperature control system to achieve high efficiency and energy saving. The temperature control system adjusts the heating power according to the real-time temperature to avoid energy waste and ensure that the battery obtains the most appropriate temperature control when needed.

Summary:

Silicone rubber lithium battery heating film is an efficient solution designed for the problem of performance degradation of lithium batteries in low temperature environments. It has the characteristics of flexible design, efficient heating, precise temperature control, etc., which can help lithium batteries maintain the best working state and is widely used in electric vehicles, energy storage systems, drones and other fields. Its customization capability and reliability make it an ideal choice for heating and protecting lithium batteries in low temperature environments.