Silicone Rubber Heater

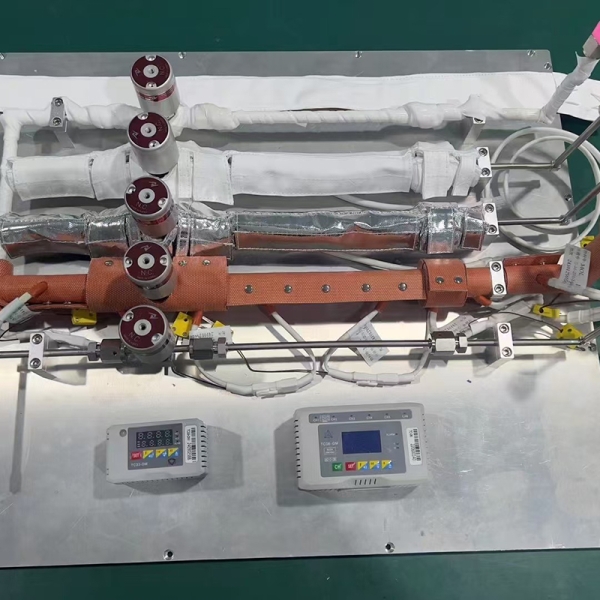

Pipe heater &tube heater

Silicone rubber heaters have excellent adaptability in pipe winding and pipeline transportation, especially in low-temperature antifreeze, temperature control and maintaining the fluidity of materials

Product Introduction

Silicone rubber heaters have excellent adaptability in pipe winding and pipeline transportation, especially in low-temperature antifreeze, temperature control and maintaining the fluidity of materials in the pipeline. The following are the specific adaptability of silicone rubber heaters in pipeline systems:

1. Antifreeze and anti-icing

In cold climates, the fluid in the pipeline is prone to freeze due to low temperature, causing blockage and affecting the normal transportation process. Silicone rubber heaters can be wrapped around the outer wall of the pipeline to provide uniform heating, ensure that the fluid remains within a suitable temperature range, and effectively prevent low-temperature freezing. They are suitable for water pipes, gas pipelines, and chemical pipelines.

2. Maintain fluid fluidity

For fluids that require a constant temperature (such as oil, fuel, chemicals, etc.), silicone rubber heaters can maintain the appropriate temperature of the liquid in the pipeline to prevent viscosity increases or flow rate decreases due to temperature changes. Especially in industries such as petroleum and food processing, silicone rubber heaters can maintain material fluidity, which helps to improve transportation efficiency and the stability of pipeline operation.

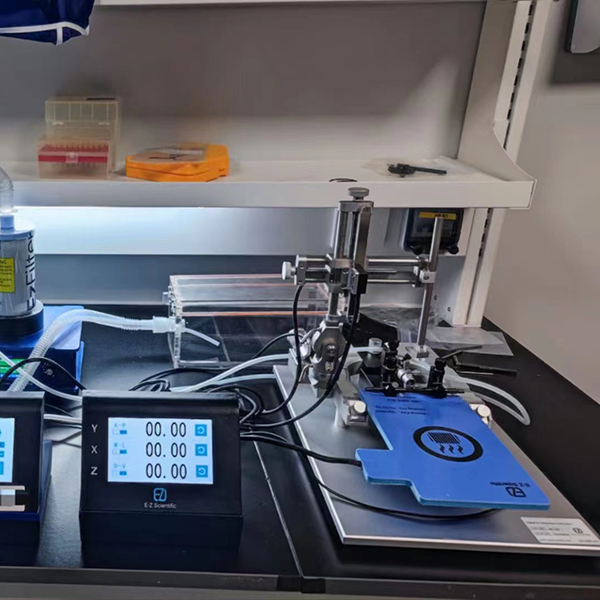

3. Flexible winding and installation

Silicone rubber heaters are soft and can be easily wrapped around pipes of various shapes. They are suitable for curved, branched or special-shaped pipes. This flexibility makes it very convenient during the pipe winding process, without affecting the appearance and internal structure of the pipe. It can also be tailored according to the length and diameter of the pipe to achieve precise heating.

4. Accurate temperature control

Silicone rubber heaters are usually equipped with temperature control devices, which can automatically adjust the pipe heating temperature according to changes in ambient temperature to ensure constant temperature in the pipe. Accurate temperature control is very critical for fluids that require high temperature or constant temperature environments. For example, in the chemical and pharmaceutical fields, the temperature in the pipe is controlled to ensure the safety and efficiency of transportation.

5. High efficiency and energy saving, strong durability

Silicone rubber heaters have efficient heat conduction characteristics and low power consumption, which can quickly heat the pipe and maintain a constant temperature while avoiding energy waste. In addition, silicone rubber materials are resistant to high temperature, corrosion and moisture, which adapts to the long-term use of pipes in harsh environments and reduces the maintenance frequency and cost of heating equipment.

6. Prevent heat loss and environmental protection

In some specific pipeline transportation systems, heat loss will affect the stability of fluid temperature. Silicone rubber heaters can be used in conjunction with thermal insulation materials to effectively reduce heat loss, reduce energy consumption, and thus reduce the impact on the environment. This heating method is green and environmentally friendly, in line with the current industry trend of low carbon and energy saving.

Typical application examples:

Industrial water pipes and wastewater pipes: In the industrial production process, it is necessary to keep the temperature of water pipes or wastewater pipes stable. Silicone rubber heaters can prevent freezing at low temperatures and maintain normal water flow.

Oil and gas pipelines: When transporting oil and natural gas in low temperature environments, silicone rubber heaters are used to maintain liquid fluidity and prevent transportation blockage or flow rate reduction caused by temperature drops.

Food and drug pipelines: In the food processing or pharmaceutical industry, pipelines used to transport syrups, oils or chemical reagents require a constant temperature environment. Silicone rubber heaters ensure that these fluids are transported at a constant temperature to ensure material quality.

Summary

Silicone rubber heaters have excellent adaptability in the field of pipe winding and pipeline transportation, providing stable heating, flexible installation and precise temperature control, ensuring the safety and fluidity of fluids during pipeline transportation. By providing effective antifreeze, insulation and constant temperature solutions for pipelines, silicone rubber heaters are widely used in industrial production, energy transportation and special fluid transmission.